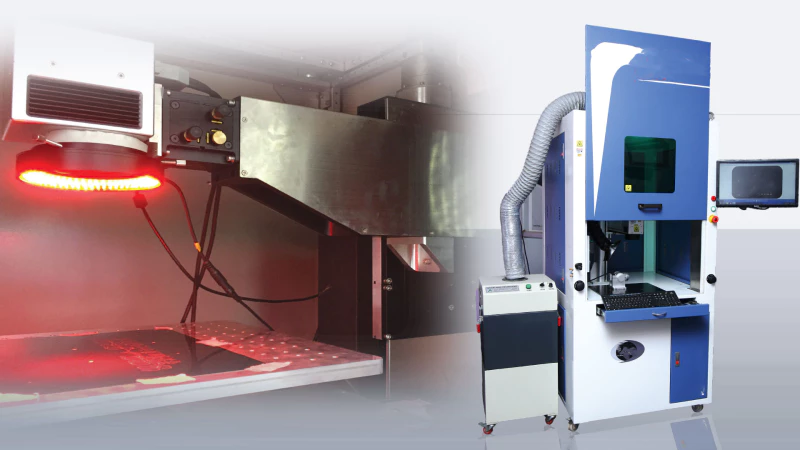

Versatile UV Laser Machines for Various Materials

The demand for UV laser machines has seen a significant surge in recent years due to their versatility in handling different materials. However, several problems can arise when operating these machines, which can affect their performance and productivity. In this guide, we will explore the common issues faced and provide viable solutions for each.

When Do Problems Arise?

Problems can occur under various circumstances – improper handling of the machine, lack of maintenance, incorrect settings, or even due to the material being used. Understanding these situations can help in quicker problem identification and resolution.

Solutions for Common Problems

Improper Handling

If the machine is not handled correctly, it can lead to several issues. To avoid this, conducting regular training for the operators on how to handle the machine properly can be beneficial.

Lack of Maintenance

Maintenance is crucial for the optimal performance of the machine. Regular cleaning and checking of the machine parts can prevent minor issues from escalating into major problems.

Incorrect Settings

Using wrong settings for different materials can affect the machine’s output. Always ensure to follow the manufacturer’s instructions when setting up the machine for different materials.

Material-Related Issues

Different materials require different laser settings. If the settings are not adjusted according to the material, it could lead to issues. Understanding the material properties and adjusting the settings accordingly can help in this regard.

Prevention Measures

To prevent these issues from recurring, it’s imperative to follow the manufacturer’s instructions and guidelines, conduct regular maintenance, and train the operators adequately. Regularly monitoring the machine’s performance can help detect any issues at an early stage and resolve them promptly.

Confirming Problem Resolution

Once the necessary steps have been taken, the best way to confirm if the issue has been resolved is by running the machine and checking if the output meets the expected standards. If the problem persists, it’s advisable to contact the technical support team of the manufacturer.

About SSJ

At SSJ, we offer an array of top-notch laser machines, including UV laser marking machines, Flying laser marking machines, Fiber laser marking machines, CO2 laser marking machines, Laser welding machines, Laser cutting machines, and Laser cleaning machines. With our state-of-the-art automated production and assembly equipment, we are committed to delivering high-quality products at competitive prices and with excellent service.

Q&A

Q1: What materials can the UV laser machines handle?

A: UV laser machines can handle a variety of materials, including plastic, glass, ceramics, and metals.

Q2: How often should I maintain my UV laser machine?

A: It’s best to conduct regular maintenance, ideally after every use.

Q3: What should I do if I’m facing issues with my machine?

A: If you’re facing any issues, it’s best to contact our technical support team who will assist you.

Q4: How can I ensure that the settings are correct for the material I’m using?

A: Always refer to the manufacturer’s instructions when adjusting the settings for different materials.

Q5: How can I prevent issues from recurring?

A: Regular maintenance, proper handling of the machine, and correct settings can help prevent issues from recurring.