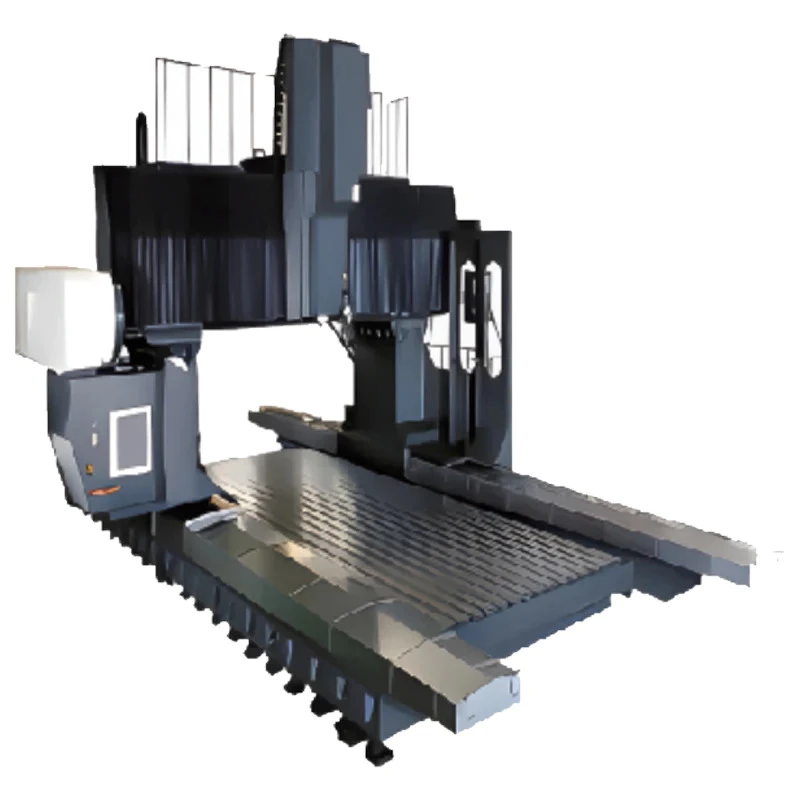

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

As one of the BL Series leaf chain manufacturers, suppliers, and exporters of mechanical products, We offer BL Series leaf chains and many other products.

Please get in touch with us for details.

The WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder is the cutting-edge solution for all your machining needs. This brand-new, vertical type machine tool boasts a maximum length of workpiece of 600mm, a spindle speed of 2000 r.p.m, and a machining capacity of medium duty.

Product Features and Functions

This state-of-the-art machine tool features a spindle bore of 300mm, a bed width of 450mm, and a spindle motor power of 15/18.5kW. With six spindles, two axes, and travel distances of 300mm and 450mm for the X and Z axis respectively, the WMX3/BP3 provides unparalleled precision and accuracy, with a positioning accuracy and repeatability of ??0.001mm.

Technical Specifications

| Model Number | WMX3/BP3 |

| Year | 2023 |

| Max. Spindle Speed (r.p.m) | 2000 r.p.m |

| Width of bed (mm) | 450 mm |

| Positioning Accuracy (mm) | ??0.001 |

| Repeatability (X/Y/Z) (mm) | ??0.001 |

| Dimension(L*W*H) | 6485*3865*3300 |

Unique Attributes and Advantages

The WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder offers several key selling points that set it apart from the competition. These include a long service life, high degree of automation, exceptional precision, capability for complex machining, improved efficiency, reduced human error, and enhanced workpiece quality.

Application Scenarios

Designed for use in machinery repair shops and manufacturing plants, this machine tool is perfect for handling medium-duty machining tasks.

About WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

This machine tool is easy to install, requires minimal maintenance, and offers a warranty of more than five years. Its core components include gear and gearbox, and it uses a FANUC CNC control system and Hongda toolpost brand.

Product Selection Guide

When choosing a CNC machining center, consider factors such as its basic principle, main types, advantages compared to traditional machine tools, common applications and industries, operation and programming basics, maintenance and upkeep requirements, and its role in improving production efficiency and quality.

About SSJ

SSJ is a leading provider of CNC machine tools and intelligent equipment in the industry. We offer high-quality CNC machine tools and intelligent equipment solutions for various industries.

Related Products

-

WFX3 CNC Machine Tool Lathe Machining Center Cylindrical CNC Tap Square Grinder

-

MJS3 Full-automatic Lathe Machining Center Roller Grinding Machine CNC Tap Chamfer Grinder

-

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

-

MCS4/MCS5 CNC Vertical Lathe Machining Center Roller Grinding Machine Tap Groove Grinder

-

LWX5 CNC Machine Tool Lathe Machining Center Cylindrical CNC Thread Grinder

-

DPX3/DPX6 CNC Vertical Lathe Machining Center Roller Grinding Machine Insert Grinder

-

PMX5 CNC Machine Tool Lathe Machining Center Cylindrical Polishing Grinder

-

BPR6 CNC Vertical Lathe Machining Center Roller Grinding Machine