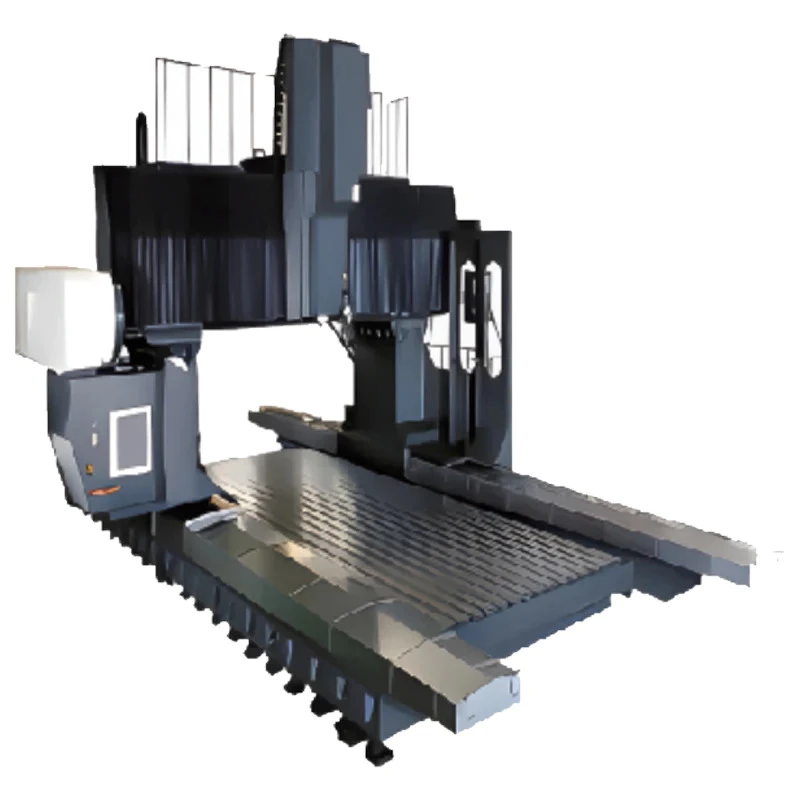

1165A Vertical High Speed Drilling CNC Lathe Machining Center

As one of the BL Series leaf chain manufacturers, suppliers, and exporters of mechanical products, We offer BL Series leaf chains and many other products.

Please get in touch with us for details.

The 1165A Vertical High Speed Drilling CNC Lathe Machining Center is a state-of-the-art machine designed for precision and efficiency. Its advanced features and robust design make it a standout product in the CNC industry, suitable for various industries such as machinery repair shops and manufacturing plants.

Product Features and Functions

The 1165A Vertical High Speed Drilling CNC Lathe Machining Center comes with an extensive range of features. It is a new model, released in 2023, equipped with a FANUC CNC Control System and Hongda Toolpost. The machine has a vertical type design with a maximum spindle speed of 2000 r.p.m., a maximum workpiece length of 600mm, and a twin spindle configuration.

The machining center boasts a medium-duty machining capacity, positioning accuracy of ??0.001 mm, and repeatability (X/Y/Z) of ??0.001 mm. It also includes a spindle motor power of 15/18.5 kW, a spindle bore of 300mm, and a bed width of 450mm. The machine's dimensions are 6485*3865*3300 and it weighs 2000 KG.

Technical Specifications

| 1165A Vertical High Speed Drilling CNC Lathe Machining Center Specifications | |||

| Model Number | 1165A | ||

| Max. Length of Workpiece (mm) | 600 | ||

| Spindle Motor Power(kW) | 15/18.5 | ||

| No. of Spindles | Twin | ||

| Number of Axes | 2 | ||

| Travel (X Axis)(mm) | 300 mm | ||

| Travel (Z Axis)(mm) | 450 mm | ||

| Weight (KG) | 2000 | ||

| Warranty | More than 5 years | ||

| Showroom Location | None | ||

| Marketing Type | New Product 2023 | ||

| Year | 2023 | ||

Unique Features and Advantages

- Highly Automated: The machine is equipped with advanced automation features to enhance productivity and minimise human error.

- Precision: The machine offers high precision with positioning accuracy and repeatability of ??0.001 mm.

- Complex Machining Capability: The machine is capable of performing complex machining tasks with its twin spindle configuration and two axes.

- Improved Efficiency: The high-speed spindle and quick tool change function improves processing efficiency.

- Quality Improvement: The machine helps to improve the quality of workpieces through its precision machining capabilities.

Applications

The 1165A Vertical High Speed Drilling CNC Lathe Machining Center is widely used in machinery repair shops and manufacturing plants. It is designed to handle a variety of machining tasks, including drilling, milling, and turning.

About SSJ

SSJ is a leading manufacturer and provider of CNC machine tools and intelligent equipment in the industry. We offer high-quality CNC machine tools and intelligent equipment solutions for various industries. SSJ is committed to providing flexible equipment procurement models such as shared machine tools, machine tool leasing, sales, and rental purchase.

Related Products

-

WFX3 CNC Machine Tool Lathe Machining Center Cylindrical CNC Tap Square Grinder

-

MJS3 Full-automatic Lathe Machining Center Roller Grinding Machine CNC Tap Chamfer Grinder

-

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

-

MCS4/MCS5 CNC Vertical Lathe Machining Center Roller Grinding Machine Tap Groove Grinder

-

LWX5 CNC Machine Tool Lathe Machining Center Cylindrical CNC Thread Grinder

-

DPX3/DPX6 CNC Vertical Lathe Machining Center Roller Grinding Machine Insert Grinder

-

PMX5 CNC Machine Tool Lathe Machining Center Cylindrical Polishing Grinder

-

BPR6 CNC Vertical Lathe Machining Center Roller Grinding Machine