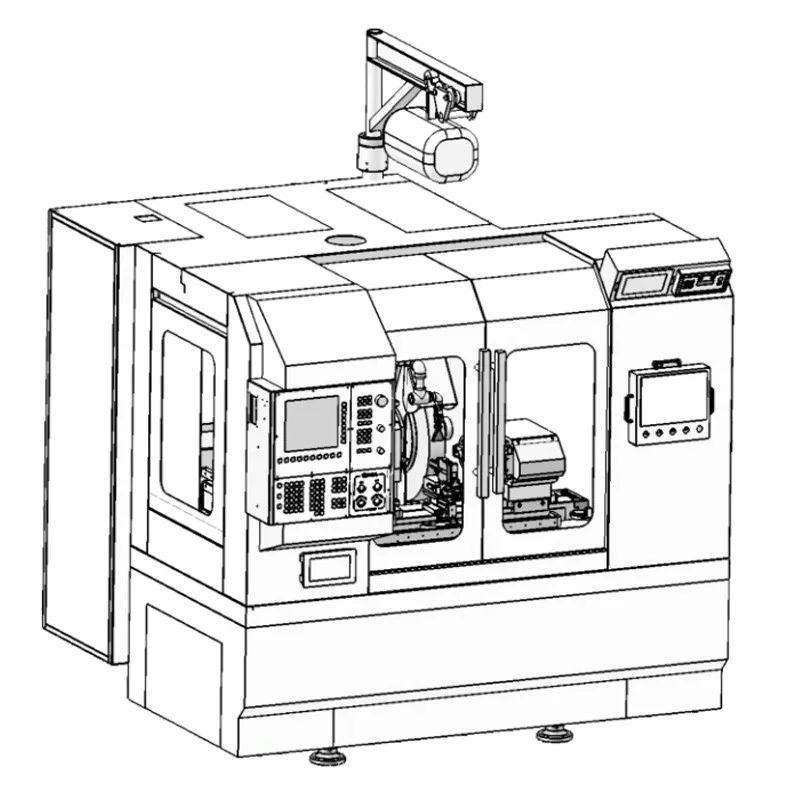

High Efficiency vertical broaching machine CNC Machining Center

As one of the BL Series leaf chain manufacturers, suppliers, and exporters of mechanical products, We offer BL Series leaf chains and many other products.

Please get in touch with us for details.

Product Overview

The high efficiency vertical broaching machine CNC Machining Center is a state-of-the-art, new generation machine tool designed for precision machining. It is highly efficient, offering medium-duty machining capacity and dual spindle operation.

Key Features and Specifications

| Feature/Specification | Detail |

|---|---|

| Condition | New |

| Year | 2023 |

| Max. Length of Workpiece (mm) | 600 |

| Max. Spindle Speed (r.p.m) | 2000 r.p.m |

| Machining Capacity | Medium Duty |

| Spindle Bore(mm) | 300 |

| Spindle Motor Power(kW) | 15/18.5 |

| No. of Spindles | Twin |

| Number of Axes | 2 |

| Travel (X Axis)(mm) | 300 mm |

| Travel (Z Axis)(mm) | 450 mm |

| Positioning Accuracy (mm) | ??0.001 |

| Repeatability (X/Y/Z) (mm) | ??0.001 |

Unique Features and Benefits

- Highly Automated: This CNC machining center is designed to provide automated and precise control over all machining processes, reducing the need for manual intervention.

- High Precision: The machine offers high precision with positioning accuracy and repeatability of ??0.001 mm, enabling the production of high-quality parts.

- Enhanced Productivity: With dual spindles and medium-duty machining capacity, the machine can handle complex machining tasks, leading to increased productivity.

- Improved Quality: Automation and precision reduce the likelihood of human error, thereby improving the quality of workpieces.

Application of the CNC Machining Center

This high efficiency vertical broaching machine CNC Machining Center has a wide range of applications in various industries, including machinery repair shops and manufacturing plants. It can perform a variety of machining tasks such as drilling, milling, broaching and more.

Introduction to CNC Machining Center

A CNC Machining Center is a sophisticated machine tool that uses computer numerical control (CNC) to perform a variety of machining processes. The key benefits of using a CNC Machining Center include high precision, consistency, versatility, and reduced labor costs. Proper installation, maintenance, and upkeep are crucial to ensuring the longevity and reliability of the machine.

Choosing the Right CNC Machining Center

To choose the right CNC Machining Center, one must consider factors such as the basic principle of the CNC process, the main types of CNC machines, the advantages of CNC over traditional machine tools, common applications and industries for CNC, the basics of CNC operation and programming, and maintenance requirements. The role of CNC Machining Centers in enhancing productivity and quality should also be considered.

About SSJ

SSJ is a leading provider of CNC Machining Centers in China. We are renowned for our product quality, reliability, technical expertise, innovation, customization capabilities, and industry compliance. We offer customized solutions to meet your specific needs. Please contact us for more information.

Related Products

-

WFX3 CNC Machine Tool Lathe Machining Center Cylindrical CNC Tap Square Grinder

-

MJS3 Full-automatic Lathe Machining Center Roller Grinding Machine CNC Tap Chamfer Grinder

-

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

-

MCS4/MCS5 CNC Vertical Lathe Machining Center Roller Grinding Machine Tap Groove Grinder

-

LWX5 CNC Machine Tool Lathe Machining Center Cylindrical CNC Thread Grinder

-

DPX3/DPX6 CNC Vertical Lathe Machining Center Roller Grinding Machine Insert Grinder

-

PMX5 CNC Machine Tool Lathe Machining Center Cylindrical Polishing Grinder

-

BPR6 CNC Vertical Lathe Machining Center Roller Grinding Machine