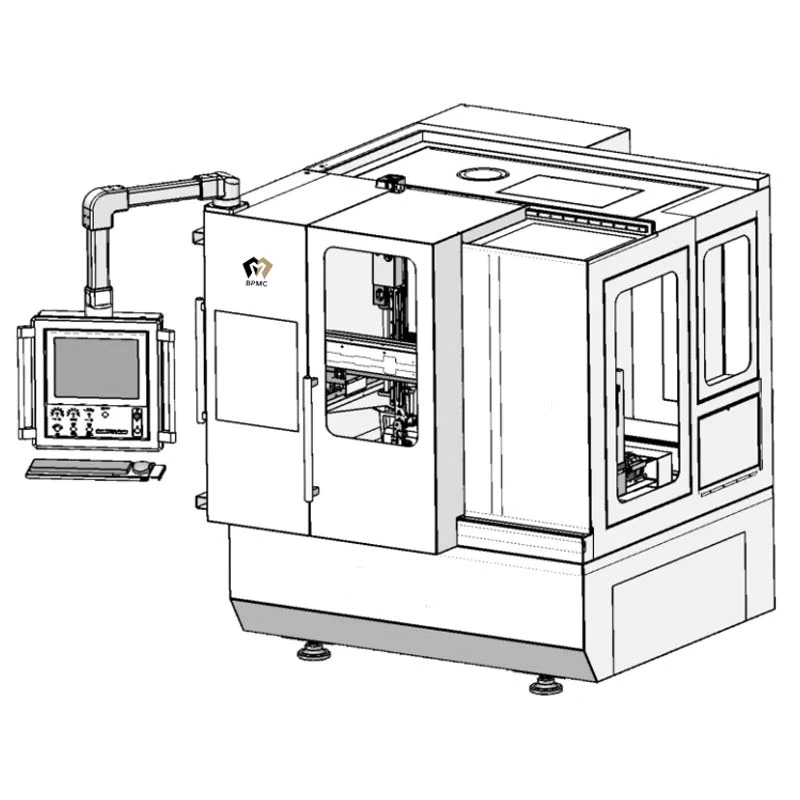

M series Vertical CNC Machining Center for Processing Plate, Disc, Shell, and Mold Parts

As one of the BL Series leaf chain manufacturers, suppliers, and exporters of mechanical products, We offer BL Series leaf chains and many other products.

Please get in touch with us for details.

The M series vertical CNC machining center is a high-quality, high-precision, low-cost, and high-efficiency machine tool, designed for processing high-precision, multi-process, and complex shaped parts such as plates, discs, shells, molds, etc. It is widely applied in industries such as automobiles, engineering machinery, aerospace, molds, hydraulic, 3C, and more.

Product Features and Details

Technical Specifications

This vertical CNC machining center boasts a new condition and a vertical type with a dimension of 1700mm*1800mm*2000mm and a weight of 2 tons. It features a spindle taper of BT40 and six spindles. The table size is 700*400mm and it's capable of a table travel of 600mm (X), 400mm (Y), and 300mm (Z).

The machine provides positioning accuracy of ?? 0.005/300mm and a repeatability of ?? 0.005 (X/Y/Z). The spindle motor power is 5.5/7.5 kW and the max table load can reach up to 8000 kg. The range of spindle speed is between 6000 and 20000 r.p.m.

With a feed speed of 32 - 48 mm/min and a rapid feed speed of 48 m/min, this machine ensures efficiency in operations. The minimum time of tool change is 4 seconds and the tool magazine capacity ranges from 10 to 40.

Control System

The CNC control system of this machine supports multiple systems including GSK, FANUC, MITSUBISHI, KND, Siemens, and DELEM, giving the user a wide range of options.

Key Selling Points

The M series vertical CNC machining center offers a competitive price and comes with a one-year warranty. Its core components include a durable gearbox and it guarantees an average time between failures of up to 15 hours.

Application and Importance

The M series vertical CNC machining center is mainly used for the processing of high-precision, multi-process, and complex shaped parts. It is applied in various industries such as manufacturing plants and horologe, providing high-precision, low-cost, and high-efficiency solutions.

Why Choose M series Vertical CNC Machining Center?

Choosing the M series vertical CNC machining center means opting for high automation, high precision, complex processing capability, improved production efficiency, reduced human errors, and improved workpiece quality.

About SSJ

SSJ is a leading manufacturer and industrial service provider of CNC machine tools and intelligent equipment in the industry. We are committed to providing customers with flexible equipment procurement models such as shared machine tools, machine tool leasing, sales, and rental purchase. Our commitment to quality, reliability, technical expertise, innovation, and industry compliance sets us apart in the CNC Machining Center market.

Related Products

-

WFX3 CNC Machine Tool Lathe Machining Center Cylindrical CNC Tap Square Grinder

-

MJS3 Full-automatic Lathe Machining Center Roller Grinding Machine CNC Tap Chamfer Grinder

-

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

-

MCS4/MCS5 CNC Vertical Lathe Machining Center Roller Grinding Machine Tap Groove Grinder

-

LWX5 CNC Machine Tool Lathe Machining Center Cylindrical CNC Thread Grinder

-

DPX3/DPX6 CNC Vertical Lathe Machining Center Roller Grinding Machine Insert Grinder

-

PMX5 CNC Machine Tool Lathe Machining Center Cylindrical Polishing Grinder

-

BPR6 CNC Vertical Lathe Machining Center Roller Grinding Machine