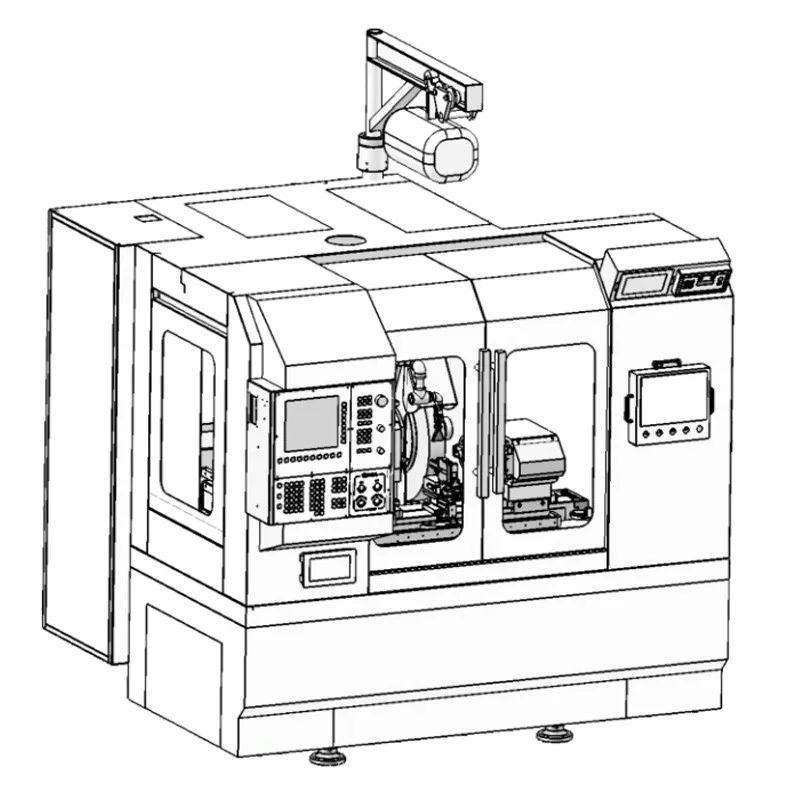

B series Bridge Type Gantry Machining Center CNC Lathe for Processing Aluminum Alloy Structural Components

As one of the BL Series leaf chain manufacturers, suppliers, and exporters of mechanical products, We offer BL Series leaf chains and many other products.

Please get in touch with us for details.

This is a new and innovative CNC lathe designed and manufactured for efficient, precise, and high-speed processing of aluminum alloy structural components. It is a versatile machine that is capable of milling, drilling, boring, and other processing techniques, all in one go.

Product Details and Specifications

This lathe is equipped with up to six spindles and offers a wide range of spindle speed, from 6000 to 20,000 r.p.m. It utilizes a BT50-190 spindle taper and has a spindle motor power of 5.5/7.5 kW. The maximum table load is 8000 kg, and the feed speed ranges from 32 to 48 mm/min.

The CNC lathe boasts a high positioning accuracy of ?? 0.005/300mm and a repeatability of ?? 0.005 for X, Y, and Z axes. The number of axes can vary, with options for 2, 3, 4, 5, 6, 7, 8, 9, or 12 axes.

The dimensions of the lathe are 1700mm*1800mm*2000mm (L*W*H), and it weighs 2 tons. The table size is 700*400mm, with a table travel of 600mm (X), 400mm (Y), and 300mm (Z). The machine is compatible with multiple CNC control systems, including GSK, FANUC, MITSUBISHI, KND, Siemens, and DELEM.

| Condition | New |

|---|---|

| Spindle Taper | BT50-190 |

| No. of Spindles | 6 |

| Type | VERTICAL |

| Dimension(L*W*H) | 1700mm*1800mm*2000mm |

Key Features and Advantages

- High-Speed Operation: The machine offers a rapid feed speed of 48 m/min and a minimum tool change time of 4 seconds.

- High Precision: The CNC lathe ensures high precision with an accuracy of 3um and a maximum torque of 955Nm.

- High Efficiency: With its multiple spindles and axes, the lathe can handle complex machining tasks in one go, significantly improving production efficiency.

- Reliability: The lathe is designed for long-lasting performance, with an average time between failures of up to 15 hours.

Applications

This CNC lathe is ideal for manufacturing plants and horologe industries, thanks to its high-speed, high-precision, and high-efficiency operation. It is particularly suitable for processing welding/die-casting aluminum alloy structural components in the new energy vehicle industry.

About the Company

SSJ is a leading manufacturer and service provider of CNC machine tools and smart equipment in China. With a focus on quality, reliability, and durability, SSJ offers top-notch products that meet and exceed customer expectations.

Why Choose Us?

At SSJ, we believe in providing our customers with flexible equipment procurement models, including machine tool leasing, sales, and rent-to-own options. We also offer customized solutions to meet unique needs and requirements.

- Thousand machine tools, available for rent in stock

- Ultra low rent, rent as needed

- Take action lightly and reduce risks

- Small investment, large returns

- Worry free service, lifetime warranty

- Renting instead of purchasing, flexible model

With SSJ, you can count on high-quality CNC machine tools and automation integration solutions that will empower your enterprise and help you achieve industry-leading performance.

For more information about our B series Bridge Type Gantry Machining Center CNC Lathe or any other products, please do not hesitate to contact us. We look forward to serving you!

Related Products

-

WFX3 CNC Machine Tool Lathe Machining Center Cylindrical CNC Tap Square Grinder

-

MJS3 Full-automatic Lathe Machining Center Roller Grinding Machine CNC Tap Chamfer Grinder

-

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

-

MCS4/MCS5 CNC Vertical Lathe Machining Center Roller Grinding Machine Tap Groove Grinder

-

LWX5 CNC Machine Tool Lathe Machining Center Cylindrical CNC Thread Grinder

-

DPX3/DPX6 CNC Vertical Lathe Machining Center Roller Grinding Machine Insert Grinder

-

PMX5 CNC Machine Tool Lathe Machining Center Cylindrical Polishing Grinder

-

BPR6 CNC Vertical Lathe Machining Center Roller Grinding Machine