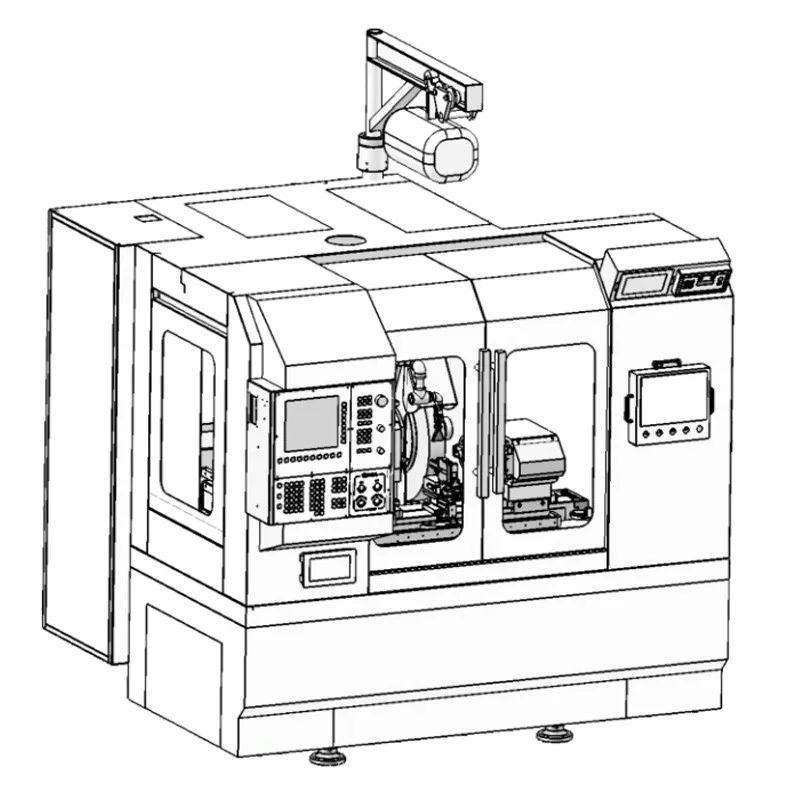

Large Linear Guideway VMC1890L Cutting Metal Working Machines CNC Lathe Machine Tool Vertical Machining Center

As one of the BL Series leaf chain manufacturers, suppliers, and exporters of mechanical products, We offer BL Series leaf chains and many other products.

Please get in touch with us for details.

Introducing the VMC1890L Large Linear Guideway, a cutting metal working machine that features state-of-the-art CNC Lathe Machine Tool technology. This vertical machining center is designed to deliver optimum performance, precision, and productivity in any manufacturing or repair setting.

Features and Functions

The VMC1890L Large Linear Guideway offers a host of impressive features and functions that sets it apart from other CNC machine tools in its class. It's not just a machine; it's a comprehensive solution that's designed to address your most demanding machining needs.

Technical Specifications

Let's dive into the technical specifications of this remarkable machine. Here are the key details:

| Condition | New |

|---|---|

| Type | VERTICAL |

| Max. Length of Workpiece (mm) | 600 |

| Max. Spindle Speed (r.p.m) | 2000 r.p.m |

| Machining Capacity | Medium Duty |

| Spindle Bore(mm) | 300 |

Unique Features and Advantages

The VMC1890L Large Linear Guideway offers several unique features and advantages that you won't find in many other CNC machine tools:

- High level of automation for increased efficiency and reduced human error

- High precision for improved workpiece quality

- Capability to handle complex machining tasks

- Improved production efficiency

Application of the VMC1890L Large Linear Guideway

The VMC1890L Large Linear Guideway is a versatile machine that can be used in a variety of applications. Here's a look at how it can be used:

Product Introduction

Our VMC1890L Large Linear Guideway is designed to deliver superior performance, ease of installation, low maintenance, and long-lasting durability. Here's what you can expect when you choose our product:

Product Selection

Choosing the right CNC machining center can be a complex task, but we're here to help. Here are some key questions to consider:

- What is the basic principle of a CNC machining center?

- What are the main types of CNC machining centers?

- How does a CNC machining center compare to traditional machine tools?

- What industries and applications are CNC machining centers commonly used in?

- What are the foundations of operating and programming a CNC machining center?

- What are the maintenance and upkeep requirements of a CNC machining center?

- How does a CNC machining center aid in improving production efficiency and quality?

About SSJ Group

SSJ Group is a leading manufacturer and industrial service provider of CNC machine tools and intelligent equipment in the industry. It has established two CNC machine tool production bases in Jiashan, Zhejiang, and Pingshan, Yibin, Sichuan, with complete casting production lines, intelligent machine tool assembly lines, and intelligent testing equipment.

Why Choose SSJ Group?

At SSJ, we're committed to delivering top-quality products and services that meet our customers' needs. Here's why you should choose us:

- Thousand machine tools, available for rent in stock

- Ultra low rent, rent as needed

- Take action lightly and reduce risks

- Small investment, large returns

- Worry free service, lifetime warranty

- Renting instead of purchasing, flexible model

Related Products

-

WFX3 CNC Machine Tool Lathe Machining Center Cylindrical CNC Tap Square Grinder

-

MJS3 Full-automatic Lathe Machining Center Roller Grinding Machine CNC Tap Chamfer Grinder

-

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

-

MCS4/MCS5 CNC Vertical Lathe Machining Center Roller Grinding Machine Tap Groove Grinder

-

LWX5 CNC Machine Tool Lathe Machining Center Cylindrical CNC Thread Grinder

-

DPX3/DPX6 CNC Vertical Lathe Machining Center Roller Grinding Machine Insert Grinder

-

PMX5 CNC Machine Tool Lathe Machining Center Cylindrical Polishing Grinder

-

BPR6 CNC Vertical Lathe Machining Center Roller Grinding Machine