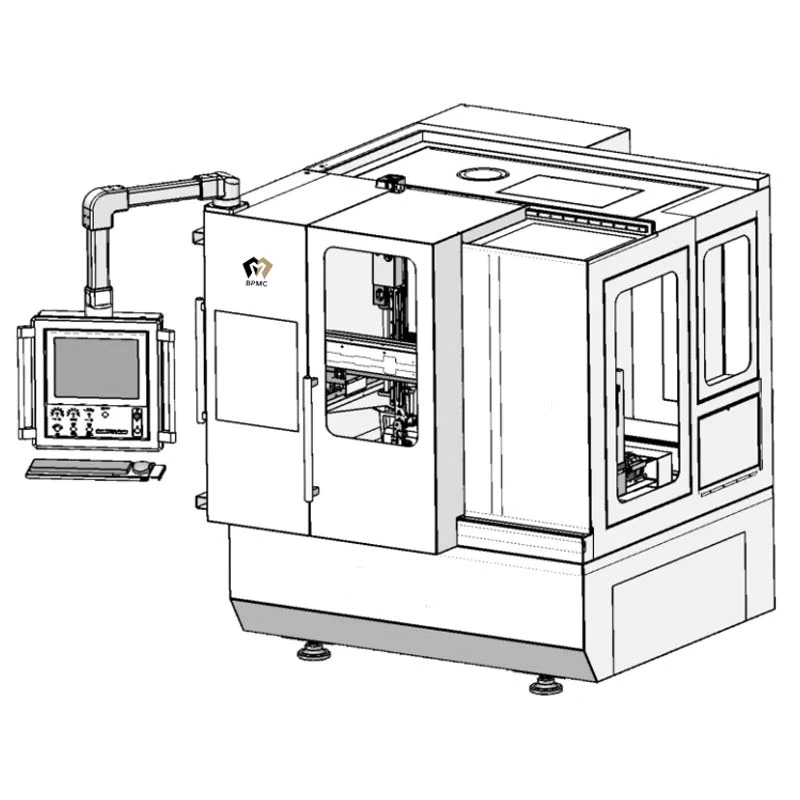

Low Price TN-500 40KVA CNC High Speed Hobbing Machine With FANUC 0i-MF Plus System

As one of the BL Series leaf chain manufacturers, suppliers, and exporters of mechanical products, We offer BL Series leaf chains and many other products.

Please get in touch with us for details.

Overview

The TN-500 40KVA CNC High Speed Hobbing Machine With FANUC 0i-MF Plus System is the ultimate solution to all your gear cutting needs. This state-of-the-art machine is designed for high-precision and efficient production of gears, incorporating computer numerical control (CNC) technology to automate the hobbing process. This ensures exceptional accuracy and productivity for a range of industries, including automotive, aerospace, power transmission, and machinery manufacturing.

Product Specifications

Significantly, the TN-500 model is new, with a vertical type and a heavy-duty machining capacity. It features a maximum spindle speed of 4500 r.p.m, a spindle bore of 190mm, and a spindle motor power of 25kw. The machine has a single spindle and two axes, with a travel of 500mm on the X-axis and 400mm on the Z-axis. It weighs 7000 kg and comes with a one-year warranty. Its color is customizable according to customer requirements.

Features and Advantages

The CNC Hobbing Machine is renowned for its high degree of automation, which reduces human error and improves the quality of workpieces. It has a fast spindle speed and high machining accuracy, which allows for complex processing and enhances production efficiency. Its key selling points include automatic operation and a high level of accuracy - DIN3974 Teeth&Helix Level 4.

Applications

The CNC high-speed hobbing machine is versatile and suitable for a wide range of industries. It is particularly useful in fields that require high-precision gears.

Product Selection and Maintenance

CNC Machining Center: The basic principle of the CNC Machining Center is to utilize CNC technology to automate the machining process. The main types of CNC Machining Centers include horizontal and vertical versions. Compared to traditional machine tools, CNC Machining Centers offer advantages such as improved accuracy, speed, and flexibility. They are commonly used in applications and industries that require high-precision machining. The operation and programming of CNC Machining Centers require a solid understanding of CNC technology and the specific software used. Regular maintenance and care are important to ensure the machine's longevity and performance. CNC Machining Centers play a crucial role in improving production efficiency and product quality.

About Our Company

SSJ is a leading provider of CNC Machining Centers in China. We pride ourselves on our product quality, reliability, technical expertise, innovation, and customer service. We welcome custom orders and promise to respond to all inquiries within 24 hours.

Related Products

-

WFX3 CNC Machine Tool Lathe Machining Center Cylindrical CNC Tap Square Grinder

-

MJS3 Full-automatic Lathe Machining Center Roller Grinding Machine CNC Tap Chamfer Grinder

-

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

-

MCS4/MCS5 CNC Vertical Lathe Machining Center Roller Grinding Machine Tap Groove Grinder

-

LWX5 CNC Machine Tool Lathe Machining Center Cylindrical CNC Thread Grinder

-

DPX3/DPX6 CNC Vertical Lathe Machining Center Roller Grinding Machine Insert Grinder

-

PMX5 CNC Machine Tool Lathe Machining Center Cylindrical Polishing Grinder

-

BPR6 CNC Vertical Lathe Machining Center Roller Grinding Machine