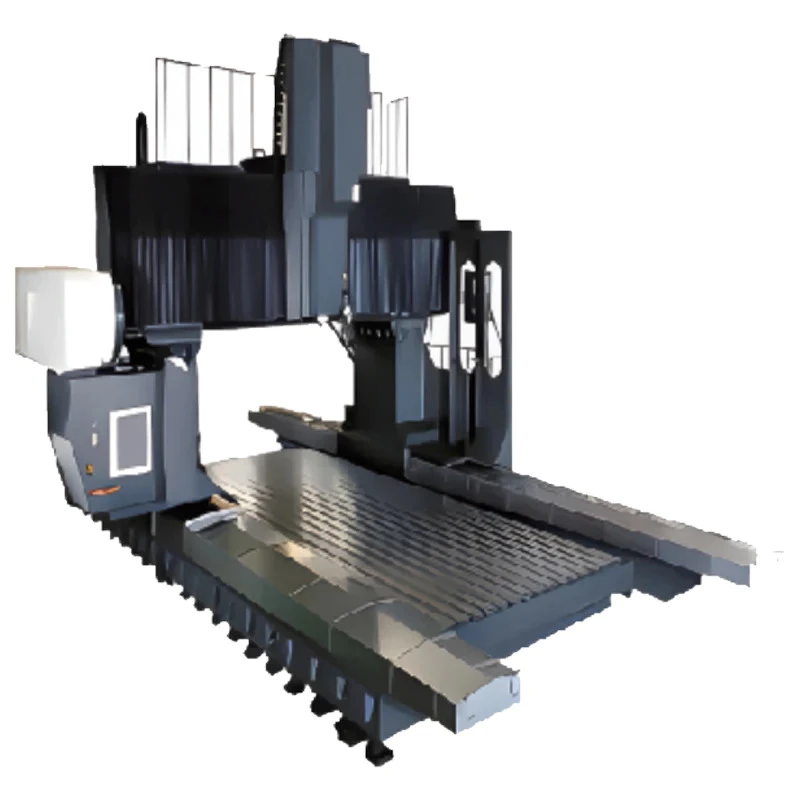

SP1020 Double Column Machining Center CNC Lathe With CNC Control

As one of the BL Series leaf chain manufacturers, suppliers, and exporters of mechanical products, We offer BL Series leaf chains and many other products.

Please get in touch with us for details.

Product Overview

The SP1020 Double Column Machining Center CNC Lathe is a state-of-the-art and high-performance machine tool engineered for heavy-duty and precise machining operations. This powerful CNC lathe is equipped with a FANUC/SIEMENS/MITSUBISHI CNC control system, offering a new level of efficiency and accuracy for your manufacturing needs.

Impressive Features

The SP1020 Double Column Machining Center CNC Lathe boasts several features that set it apart:

- Superb Rigidity: Its robust double column structure offers exceptional rigidity and stability during machining operations. This structure minimizes vibrations, ensuring high-precision results.

- Large Workpiece Capacity: The spacious worktable and generous load capacity of the SP1020 make it suitable for accommodating large and heavy workpieces.

- Versatility: This machining center provides multi-axis capabilities, allowing for complex machining tasks and accommodating a wide range of workpiece sizes and geometries.

- High Productivity: With its powerful spindle and efficient tool changing system, the SP1020 enables fast and efficient production.

- Advanced Control System: The machine features a user-friendly control interface, making programming, operation, and monitoring of machining processes simple and straightforward.

Technical Specifications

| Condition | New |

| Max. Length of Workpiece (mm) | 600 |

| Spindle Bore(mm) | 300 |

| Spindle Motor Power(kW) | 15/18.5 |

| No. of Spindles | Twin |

| Number of Axes | 2 |

| Travel (X Axis)(mm) | 300 mm |

| Travel (Z Axis)(mm) | 450 mm |

| Positioning Accuracy (mm) | ??0.001 |

| Repeatability (X/Y/Z) (mm) | ??0.001 |

| Weight (KG) | 2000 |

| Warranty | More than 5 years |

Applications

The SP1020 Double Column Machining Center is ideal for various industries, including:

- Automotive: It is used for machining large engine blocks, transmission housings, chassis components, and other automotive parts.

- Aerospace: The SP1020 is utilized in the aerospace industry for machining structural components, aircraft frames, wing spars, and other large-scale aerospace parts.

- Mold and Die Making: It is widely employed for machining large molds and dies used in plastic injection molding, die casting, and other molding processes.

- Heavy Machinery: The SP1020 is suitable for machining components of heavy machinery, such as construction equipment, industrial machinery, and energy-related equipment.

About SSJ

SSJ is a leading manufacturer and industrial service provider of CNC machine tools and intelligent equipment in the industry. We have established two CNC machine tool production bases in Jiashan, Zhejiang and Pingshan, Yibin, Sichuan, with complete casting production lines, intelligent machine tool assembly lines, and intelligent testing equipment. We offer high-quality CNC machine tools and intelligent equipment solutions for the industry.

Related Products

-

WFX3 CNC Machine Tool Lathe Machining Center Cylindrical CNC Tap Square Grinder

-

MJS3 Full-automatic Lathe Machining Center Roller Grinding Machine CNC Tap Chamfer Grinder

-

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

-

MCS4/MCS5 CNC Vertical Lathe Machining Center Roller Grinding Machine Tap Groove Grinder

-

LWX5 CNC Machine Tool Lathe Machining Center Cylindrical CNC Thread Grinder

-

DPX3/DPX6 CNC Vertical Lathe Machining Center Roller Grinding Machine Insert Grinder

-

PMX5 CNC Machine Tool Lathe Machining Center Cylindrical Polishing Grinder

-

BPR6 CNC Vertical Lathe Machining Center Roller Grinding Machine