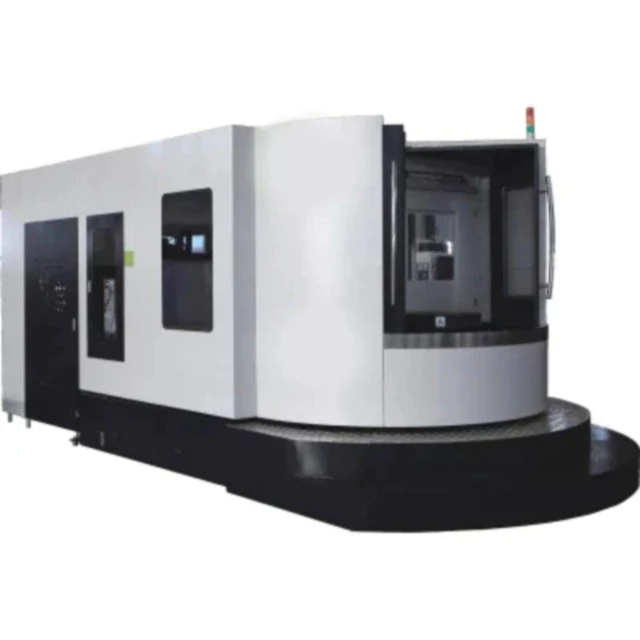

BPF4 F6 6 Transfer Station 5 Axis CNC Machine Tool Lathe Machining Center Grinder for Metal Cutter

As one of the BL Series leaf chain manufacturers, suppliers, and exporters of mechanical products, We offer BL Series leaf chains and many other products.

Please get in touch with us for details.

Introducing the BPF4 F6 6 Transfer Station 5 Axis CNC Machine Tool Lathe Machining Center Grinder for Metal Cutter - a state-of-the-art, medium-duty, vertical lathe machine designed for precision metal cutting and grinding.

Product Features and Functionality

Equipped with a powerful 15/18.5 kW spindle motor, 6 spindles, and a maximum spindle speed of 2000 r.p.m, this CNC Machine Tool Lathe is capable of delivering outstanding performance and precision. It also features a sophisticated FANUC CNC control system, and a high-quality Hongda tool post, promising long service life.

Technical Specifications

| Max. Length of Workpiece (mm) | 600 |

| Max. Spindle Speed (r.p.m) | 2000 r.p.m |

| Spindle Motor Power(kW) | 15/18.5 |

| No. of Spindles | 6 |

| Number of Axes | 2 |

| Travel (X Axis)(mm) | 300 mm |

| Travel (Z Axis)(mm) | 450 mm |

| Weight (KG) | 2000 |

| Warranty | More than 5 years |

Unique Features and Advantages

- High level of automation and precision

- Ability to handle complex machining tasks

- Improves production efficiency

- Reduces human error

- Enhances workpiece quality

Application Scenarios

This CNC Machining Center is particularly beneficial for industries such as machinery repair shops and manufacturing plants. Its superior machining capacity and long service life make it a reliable choice for demanding applications.

Product Overview and Maintenance

The BPF4 F6 6 Transfer Station 5 Axis CNC Machine Tool Lathe Machining Center Grinder offers remarkable advantages in terms of installation, maintenance, and upkeep. It's designed for long-term usage, with a warranty of more than 5 years on core components such as the gear and gearbox.

Product Selection Guide

When it comes to choosing a CNC Machining Center, several factors should be considered. These include the basic principles of CNC machining, the main types of CNC machining centers, the advantages of CNC machining centers compared to traditional machine tools, the common applications and industries for CNC machining centers, the basics of operating and programming a CNC machining center, the maintenance and upkeep requirements of a CNC machining center, and the role of a CNC machining center in improving production efficiency and quality.

About SSJ

SSJ is a leader in the Chinese CNC Machining Center market, with a strong emphasis on product quality and reliability, technical expertise and innovation, customization and flexibility, and certification and industry compliance. We are committed to meeting the evolving needs of our customers and providing top-notch CNC machine tools and solutions.

Related Products

-

WFX3 CNC Machine Tool Lathe Machining Center Cylindrical CNC Tap Square Grinder

-

MJS3 Full-automatic Lathe Machining Center Roller Grinding Machine CNC Tap Chamfer Grinder

-

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

-

MCS4/MCS5 CNC Vertical Lathe Machining Center Roller Grinding Machine Tap Groove Grinder

-

LWX5 CNC Machine Tool Lathe Machining Center Cylindrical CNC Thread Grinder

-

DPX3/DPX6 CNC Vertical Lathe Machining Center Roller Grinding Machine Insert Grinder

-

PMX5 CNC Machine Tool Lathe Machining Center Cylindrical Polishing Grinder

-

BPR6 CNC Vertical Lathe Machining Center Roller Grinding Machine