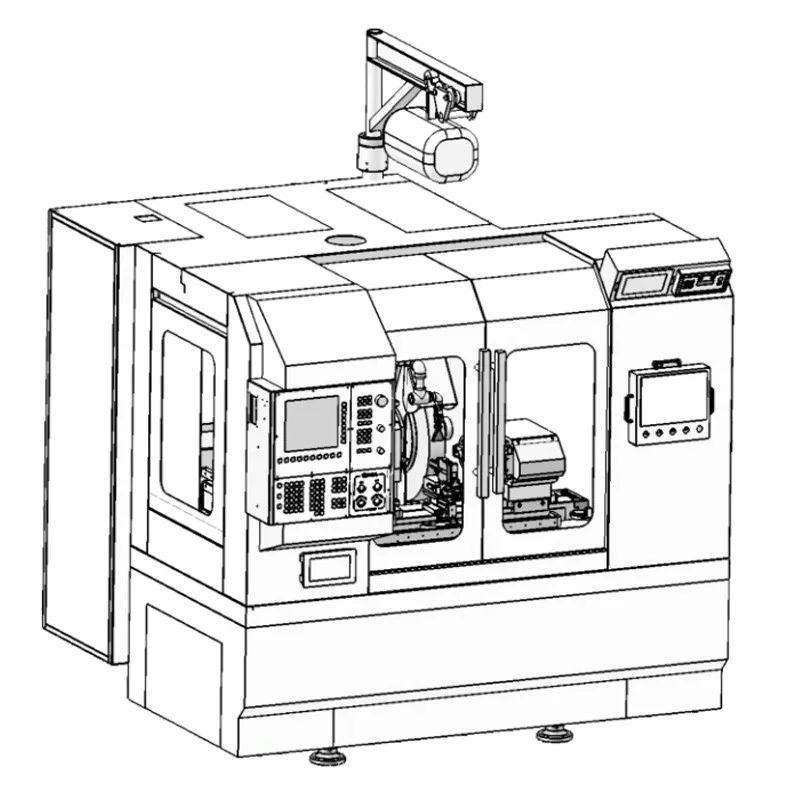

V11B High Speed High Rigidity CNC Lathe Vertical Machining Center

As one of the BL Series leaf chain manufacturers, suppliers, and exporters of mechanical products, We offer BL Series leaf chains and many other products.

Please get in touch with us for details.

The V11B High Speed High Rigidity CNC Lathe Vertical Machining Center is a new and innovative product introduced in 2023. It is a high-performance piece of machinery designed for various machining tasks. With its high speed and rigid structure, the V11B is ideal for medium-duty tasks in machinery repair shops and manufacturing plants.

Product Features

The V11B direct spindle high-speed machining center is designed with a vertical frame layout, with columns fixed on the bed. The spindle box moves up and down along the columns (Z direction), the slide seat moves longitudinally along the bed (Y direction), and the workbench moves laterally along the slide seat (X direction). All three axes use linear guides, replacing sliding friction with rolling friction, which makes the movement speed faster and meets the requirements of high speed and precision.

Product Specifications

| Condition: | New |

| Type: | Vertical |

| Year: | 2023 |

| Max. Length of Workpiece (mm): | 600 |

| Max. Spindle Speed (r.p.m): | 2000 r.p.m |

| Machining Capacity: | Medium Duty |

| Spindle Bore (mm): | 300 |

| Width of bed (mm): | 450 mm |

| Spindle Motor Power (kW): | 15/18.5 |

| No. of Spindles: | Twin |

| Number of Axes: | 2 |

| Travel (X Axis) (mm): | 300 mm |

| Travel (Z Axis) (mm): | 450 mm |

| Positioning Accuracy (mm): | ??0.001 |

| Repeatability (X/Y/Z) (mm): | ??0.001 |

| Dimension (L*W*H): | 2260*1780*2800 |

| Model Number: | V11B |

| Voltage: | - |

| CNC Control System: | FANUC |

| Toolpost Brand: | Hongda |

| Tool Post Stations: | 8, 6 |

| Weight (KG): | 2000 |

| Warranty: | More than 5 years |

| Applicable Industries: | Machinery Repair Shops, Manufacturing Plant |

| Key Selling Points: | Long Service Life |

| Showroom Location: | None |

| Marketing Type: | New Product 2023 |

| Machinery Test Report: | Provided |

| Video outgoing-inspection: | Provided |

| Warranty of core components: | 1 Year |

| Core Components: | Gear, Gearbox |

| Worktable size: | 500*1000mm |

| T -slot (N-W*D): | 5-18*100mm |

| X axis travel: | 850mm |

| Y axis travel: | 500mm |

| Z axis travel: | 550mm |

| L*W*H: | 2460*2355*2860mm |

| Max. load bearing of worktable: | 500kg |

| Machine weight: | 5500kg |

Unrivaled Efficiency

The V11B High Speed High Rigidity CNC Lathe Vertical Machining Center is noted for its high efficiency in operations. It can achieve processes such as milling, drilling, expanding, boring, reaming, and tapping. It is mainly used in mechanical processing industries such as military, mining, automotive, molds, and instruments, etc. It can be used to process various high-precision, multi-process, and complex shaped parts. It is suitable for small and medium-sized batch, multi-variety production, and can also enter automatic assembly line production.

Why Choose SSJ

SSJ is a leading manufacturer and industrial service provider of CNC machine tools and intelligent equipment in the industry. We have established two CNC machine tool production bases in Jiashan, Zhejiang and Pingshan, Yibin, Sichuan, with complete casting production lines, intelligent machine tool assembly lines, and intelligent testing equipment. We are equipped with a professional R&D, manufacturing, and sales team, aiming to provide high-quality CNC machine tools and intelligent equipment solutions for the industry.

Flexible Models and Excellent Services

SSJ is committed to providing customers with flexible equipment procurement models such as shared machine tools, machine tool leasing, sales, and rental purchase while connecting the casting, main components, and whole machine assembly industry chain. We offer worry-free service with a lifetime warranty. Renting instead of purchasing, flexible models are our strengths.

Quality and Innovation

SSJ has always been at the forefront of innovation and quality in the CNC Machining Center market. Our products are known for their quality, reliability, and durability. We continuously monitor the CNC Machining Center consumer market and customer needs and make technical adjustments according to the market.

Customization and Flexibility

We accept custom orders. If you provide a customized solution, please contact us. We will reply to your message within 24 hours. We welcome customers to customize their orders.

Certification and Industry Compliance

SSJ has always been committed to certification and industry compliance. We always ensure that our CNC Machining Centers comply with all relevant industry standards.

Conclusion

In conclusion, the V11B High Speed High Rigidity CNC Lathe Vertical Machining Center is a high-quality, reliable, and efficient machine tool that is perfect for various machining tasks. Its unique features and advantages make it an essential tool in many industries. With SSJ as your provider, you can expect high-quality products and excellent services.

Related Products

-

WFX3 CNC Machine Tool Lathe Machining Center Cylindrical CNC Tap Square Grinder

-

MJS3 Full-automatic Lathe Machining Center Roller Grinding Machine CNC Tap Chamfer Grinder

-

WMX3/BP3 CNC Machine Tool Lathe Machining Center Cylindrical Grinder

-

MCS4/MCS5 CNC Vertical Lathe Machining Center Roller Grinding Machine Tap Groove Grinder

-

LWX5 CNC Machine Tool Lathe Machining Center Cylindrical CNC Thread Grinder

-

DPX3/DPX6 CNC Vertical Lathe Machining Center Roller Grinding Machine Insert Grinder

-

PMX5 CNC Machine Tool Lathe Machining Center Cylindrical Polishing Grinder

-

BPR6 CNC Vertical Lathe Machining Center Roller Grinding Machine