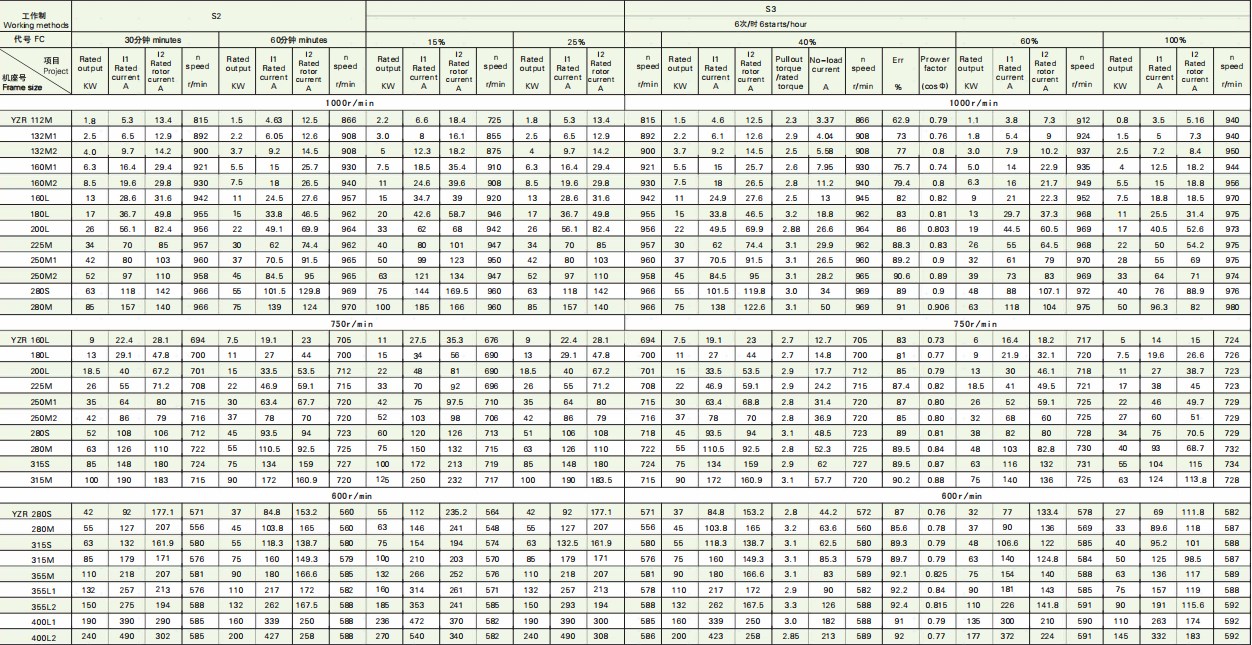

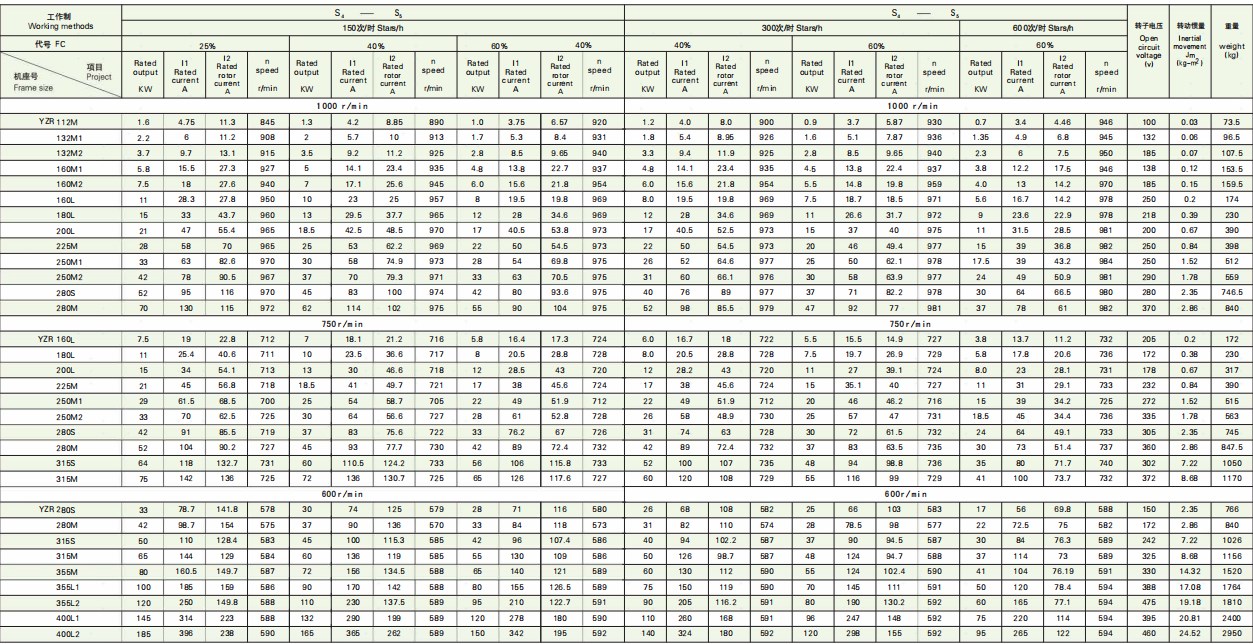

YZR&YZ series three-phase asynchronous motors for hoisting and metallurgy

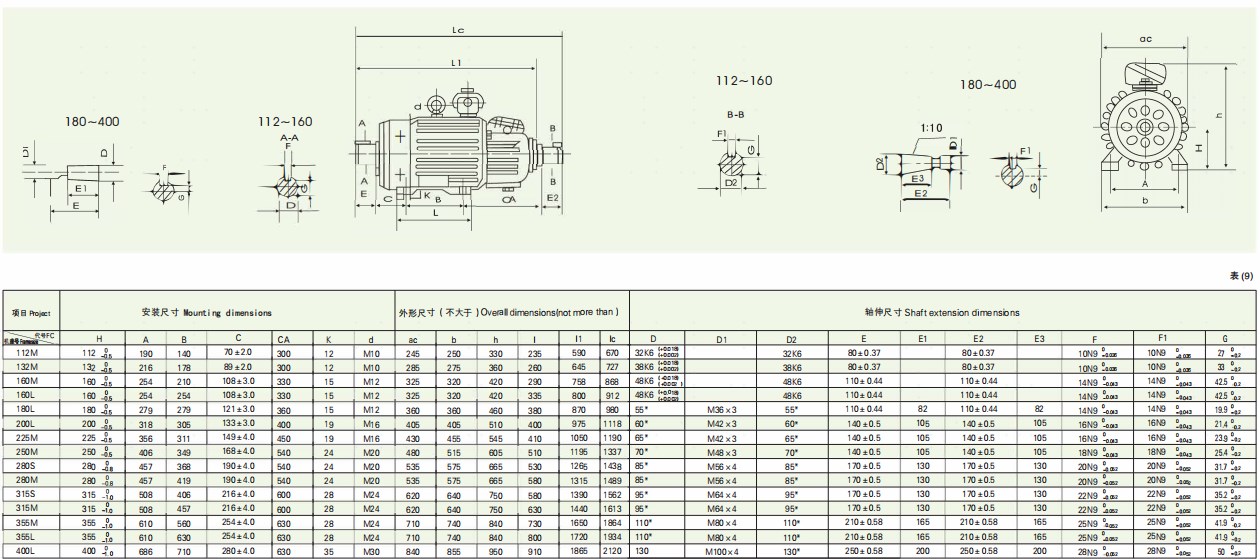

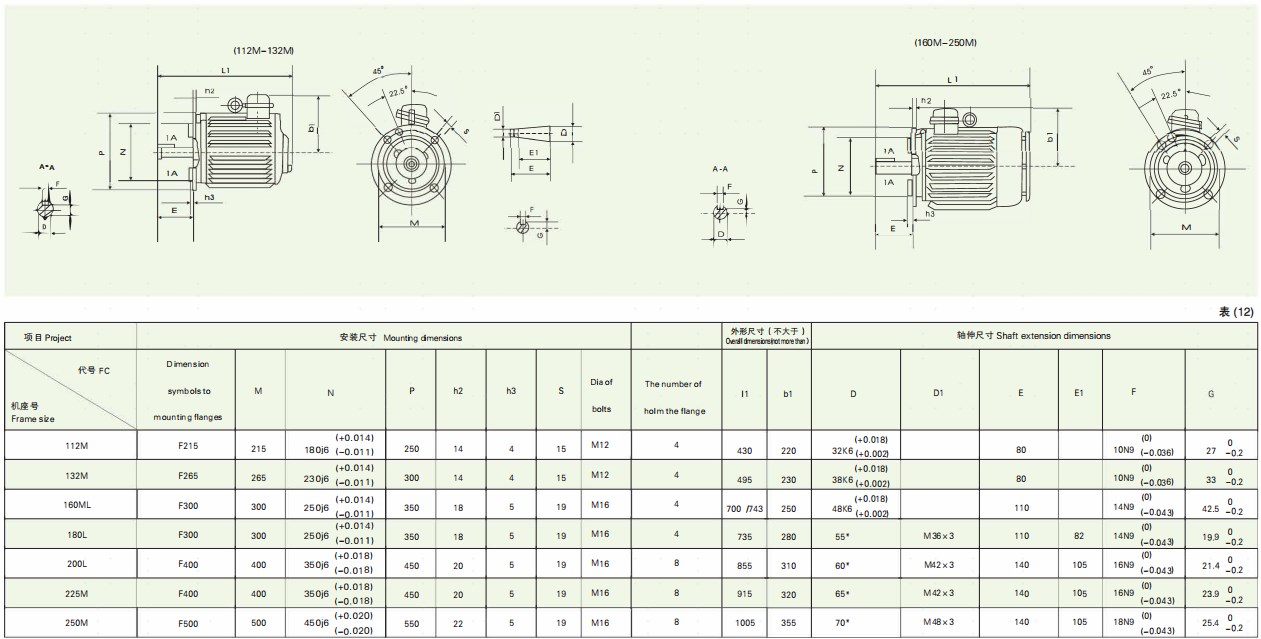

YZR IMI 112-400 appearance and installation dimensions

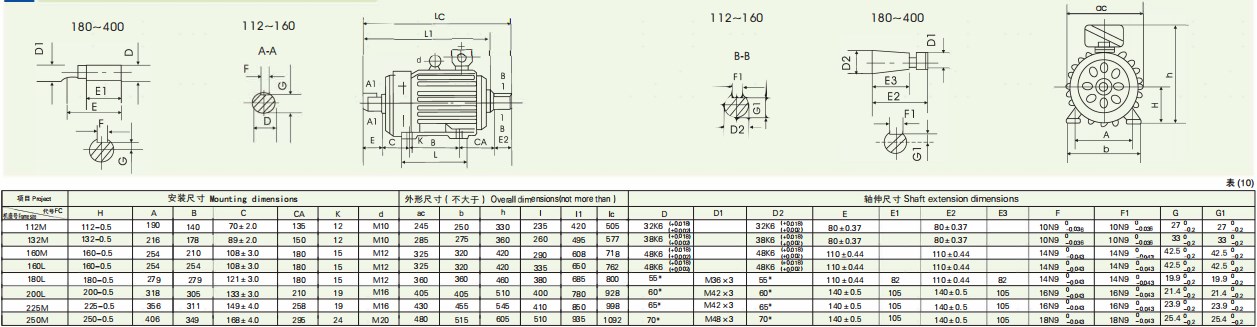

Appearance and installation dimensions of YZ IMI 112-250

Appearance and installation dimensions of YZR IM3 installation method

Appearance and installation dimensions of YZ IM3 installation method

product description

1.1. YZR and YZ series are the latest designed motors, which have the characteristics of large overload capacity and high mechanical strength. They are especially suitable for thousands of drives.

Various types of metallurgical and lifting machinery or other similar equipment. The YZR series is a wound rotor motor, and the YZ series is a cage motor.

1.2. The motor can operate normally under the following environmental conditions:

(1) The cooling medium temperature does not exceed 60°

C (metallurgical motor) or 40. C (motor for lifting)

(2) The altitude does not exceed 1,000 meters.

(3) Frequent and significant mechanical vibration and impact.

1.3. The motor can work normally under the following load conditions

(1) Frequent starts and reversals

1.4. The rated frequency of the motor is 50 Hz and the rated voltage is 380 volts.

1.5. Connection method: The stator windings with power of 132 dry watts and small 132 dry watts use Y connection method, and the rest use Y connection method.

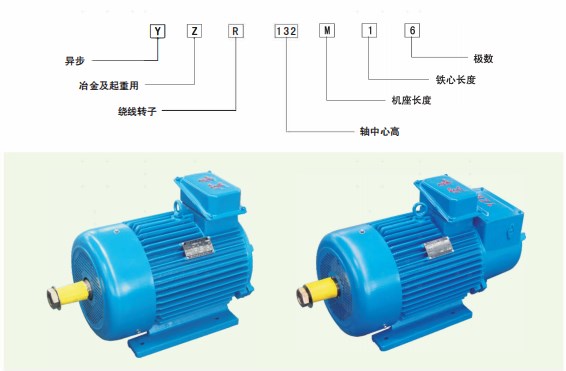

1.6. Model description

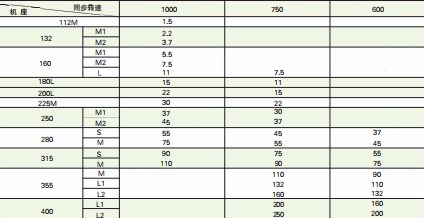

1.7. Output power and speed

1.8. In the reference working mode, the guaranteed value of the ratio of the maximum torque of the YZR series motor at the rated voltage to the rated torque

1.9. In the reference working mode, the guaranteed value of the ratio of the maximum torque of the YZ series motor at the rated voltage and the locked-rotor torque to the rated torque

WHY CHOOSE US?

Custom Design

Related products

-

1165A Vertical High Speed Drilling CNC Lathe Machining Center

-

2BV China Made Electric Industrial Liquid Ring Vacuum Pump

-

2BV high performance limited vacuum liquid ring water ring vacuum pump

-

2BV Single Stage Water Ring Vacuum Pump

-

2SK China Double Stage Water Ring Oilless Vacuum Pump

-

2SK Electric Double Stage Liquid Ring Vacuum Pump

-

2SK Heavy Duty Industrial Two Stage Water Ring Vacuum Pump

-

2X Double Stage Rotary Vane Vacuum Pump For Vacuum Coating

company advantage:

1. Large production capacity and fast delivery.

2. Strict quality control inspection rules: all products must pass 100% inspection before delivery.

3. Provide OEM/ODM service

4. 24-hour online service.

5. Real-time quotation query

6. High quality, high reliability and long product life.

7. Professional manufacturers provide competitive prices.

8. Diversified, experienced skilled workers.

Working Condition

1. Ambient Working Temperature: Ambient temperature varying with seasons should be between 40℃ and -15℃.

2. Altitude: Not over 1000m above sea level.

3. The average relative humidity in the most moisture month is 90%.

4. Operation Mode(duty): S1.

1.Regular Inspections: Perform regular visual inspections of the motor to identify any signs of wear, damage, or loose connections.

2.Cleaning: Keep the motor clean and free from dirt, dust, and debris.

3.Lubrication: Follow the manufacturer’s recommendations for lubricating the motor bearings, if applicable.

4.Check Cooling System: Ensure that the motor’s cooling system is functioning properly.

Ordering information and notes

Shaft extension (tapered shaft/straight shaft), shaft diameter size and installation type, etc.

When ordering, please specify the type of motor, rated output,

speed, voltage, frequency, and mounting arrangement.

2If there are special requirements, other pole numbers, other structures, and other components can be provided after mutual agreement.

Installed motors can also be equipped with tachometer generators, photoelectric encoders, electromagnetic

Brakes, electric heaters, thermal sensors, etc. can also be developed for users with other rated voltages.

Voltage, frequency, and frequency range of variable frequency motors.

If any special requirement is needed. The different pole numbers,

construction, and mounting arrangements are provided, we can also

fit a tacho generator, optical encoder, electromagnetic brake and

electrical heater, and heat sensor. We can also undertake design

to customer’s specific requirements.

3. The largest frame number currently produced is YZP560.

The biggest frame Number that has been made is YZP560.

4. The technical data in this sample are for reference only and are subject to change.

This sample’s engineering data only supplies the reference,

contains the change